Electronics Service and Repair

Rework Updates

RVI understands how these efforts require quick turnkey activities related to modifications and updates. Examples of these activities include:

- Implementing an ECO change to an existing application purged from the field

- Modifying an application to meet additional specification requirements

- Screen verification testing to ensure units are in complete compliance (electrical and/or mechanical aspects)

- Partnering with OEM's to meet an end client obligations

RVI Automatic Test Equipment (RATE)

RVI has the experience and skills to design, build, and maintain a scalable fleet of Automatic Test Equipment (ATE) based around our customers' needs and expectations.

- Full wattage range of 1w - 10,000+w

- Tests designed to simulate and verify acceptance of application requirements

- All test descriptions developed and programmed by our internal resources

- All fixtures and harness connections designed and developed by internal resources

- Meeting the goal of no testing downtime greater than 1/2 hour with internal backup systems and knowledge of system(s) development

- Strategically placed within the repair operation for improved service efficiencies

- All test data is retained on the network to be easily recalled when needed

- All test platforms are custom designed, LabVIEW based

RATE-Audio

Our custom designed RVI Automatic Test Equipment (RATE) Audio Analyzer provides the following measurements for each repaired unit:

- Frequency Response

- Total Harmonic Distortion (THD)

- Signal to Noise Ration (SNR)

- Total Output Power in Wattage

- AC Level

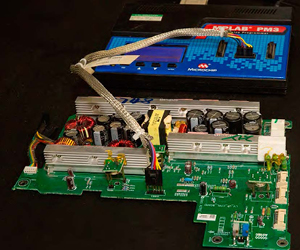

Firmware Updates

RVI has the ability to update applications with the latest version of firmware provided by performing entire software downloads or specifically programmed hex codes per update requirements.

System capabilities:

- Program memory, configuration bits, ID locations, and calibration data into PICmicro devices

- Verify PICmicro microcontrollers are blank

- Verify code in the target microcontroller matches firmware

- Install hex code files supplied by the client

- Program unique serialized ID numbers into firmware using Serial Quick Turn Programming (SQTP) files

- Program many Microchip Memory parts

Firmware Update Equipment Programmers:

- Microchip Pro Mate II AC004004

- Microchip PICkit 2

- Microchip MPLAB ICD3 (2)

- Microchip MPLAB PM3 (2)

- ATMEL AVRISP

- ST Raisonance R LINK

Application Features:

- Updating existing firmware or writing completely new firmware

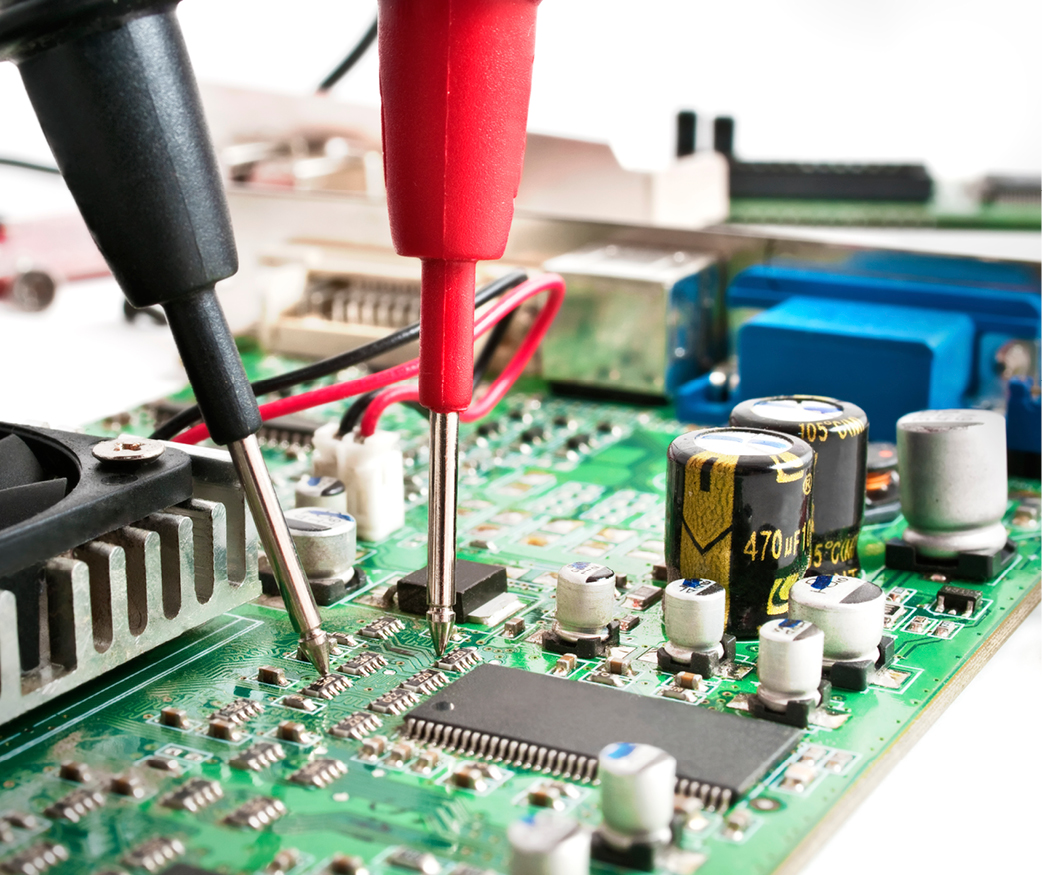

Soldering

RVI has over 28 years of experience in soldering a variety of electronic applications with capabilities consisting of:

- Meeting ICP-610 standards

- Complete coverage of fine pitch soldering requirements

- Capable of providing both RoHS and Non-RoHS controlled soldering environments

Additional capabilities include:

- High magnification microscopes

- All stations are equipped with Metcal soldering equipment

- Hakko de-soldering stations throughout our operation

Soldering Equipment

Soldering Stations

- Metcal MX-500P-11 and Metcal PS2E-01

De-Soldering Stations

- Hakko 471

- RVI Proprietary Vacuum System

Fine Pitch Soldering

- Olympus SZ-STS precision microscope

- Solder Pots

- Air-VAC PCBRM15 (lead-free) and Air-VAC PCBRM12 (leaded)

Failure Analysis

RVI offers four levels of failure analysis depending upon your needs. These include:

Level 1: Identified failed components

Sample Level 1 Report

Standard data collected and included as part of each service related activity

Level 2: Trend analysis via part number

Sample Level 2 Report

Providing an enhanced level of data analysis, charting, and reporting

Level 3: Engineer analysis of root cause

Sample Level 3 Report

Detailed reporting describing root cause, recommendations for enhancements and photographs in support of descriptions

Level 4: Component analysis

Sample Level 4 Report

Cross section of component and detailed analysis report including photographs.

(Outside source utilizing decapsulating chemicals and electron scanning microscopes.) RVI utilizes an

OPLENIC SZM745T trinocular microscope for failure analysis photos.

Burn-In

RVI has the technical knowledge to meet any burn-in requirements:

- Design and build of burn-in application

- Monitoring and testing per customer requirements

- Data generation and test outcome analysis

Specific Hardware

- Horner HENX221DF Controller

- HP 34970A Data Acquisition Unit

- Card 34902A 16 Channel Multiplexer (2)

- TDI RBL 488 100-300-2000 Dynamic Load (3)

Application Features

- Racks (5, 5 drawers per rack) Dynamic Loading or Resistive Loading

- Continuous monitoring of all DC channels

- Programmable On/Off cycling

- Burn-in programs are custom designed, LabVIEW based