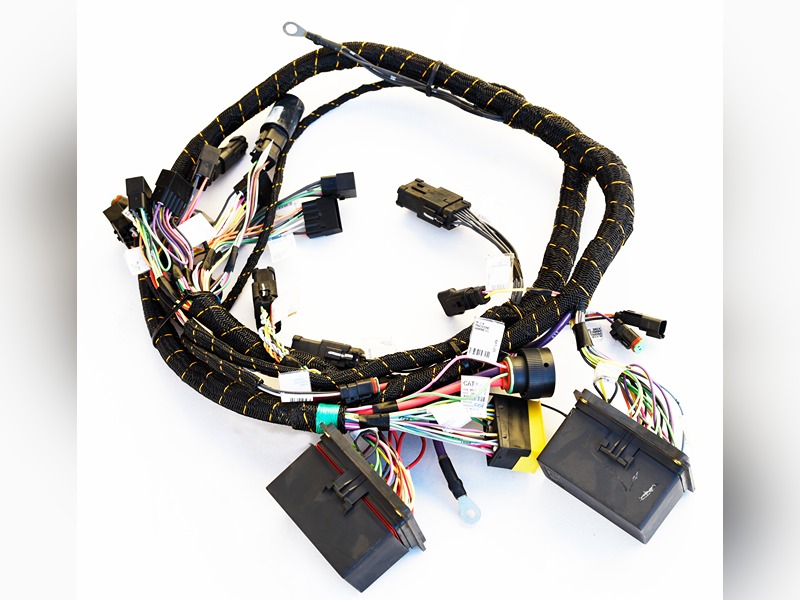

Cable Assemblies & Wire Harnessing

RVI offers a wide range of services and support

The technical team at RVI has been designing and building harness assemblies for our test equipment for over 30 years. It was a natural fit when our clients began asking us to design cabling, wiring and harnessing assemblies for other application specific requirements. We build rectangular, circular, power/high voltage and RF assemblies for many different applications in the industrial, medical, military, aerospace and transportation markets, to name a few.

Value Added Services

- Printed Circuit Board (unique assembly, enhancements and modifications)

- Wire Harness Assembly

- Cable Harness Assembly

- Box Build Assemblies

- Panel Build Assemblies

- Kitting

- Wire Marking and Label Wrapping

- Tie Wrapping

- Wire Braiding

- Potting

- Soldering

- Crimp Force Monitoring (CFM)

- Pull Testing

- Insulation Testing

- Continuity and Full Functional Testing

- Resistance Testing

- Wire Stripping

- Label & Bar Coding

Design Engineering

- AutoCAD and Drawing Preparation

- Reverse Engineering

- Failure Analysis / Product Improvement Evaluation

- Process Development (process / test description)

- Configuration Controlled Harness Boards with Integrated Testing

- Design & Build of Unique Test Fixtures/Equipment

- Hipot Testing

- Burn-In Design / Build / Testing

- Documentation Control for Custom Prints and BOMs

- Prototype, Pre-Production, and First Article Runs if Required

- Key Metrics Tracking / Analyzed

Quality & Compliance

- ISO 9001

- IPC 610 Standards

- Electronic Quality Manuals

- RoHS

- Counterfeit Prevention Plan for Sourcing Components